Intellibend Software features

-

Simple programming interface on 21.5" multi touch screen

-

Full CNC control of all servo axis

-

Updated 3D animated simulation with collision detection

-

Integrated batch control and piece counting

-

Network connectivity built-in for remote technical support and troubleshooting

-

Full undo/redo Windows 10 functionality

-

OPC UA functionality for "IIOT" implementation

-

Custom I/O functions available

-

Automatic save/backup utilities

-

Automatic call and fault recovery with Fanuc robotics

-

Software updates provided at no charge

-

Built in notes columns

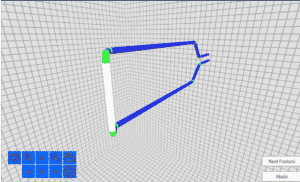

3D Program Simulation

Animated simulation generates wire form creation and machine movements

Design mode allows selection of segments for editing corresponding CNC code

Moveable 360 degree camera view of generated wire form

Run complete simulation at once or step by step

Collision detection of wire form with itself and the machine

Mechanical Features

-

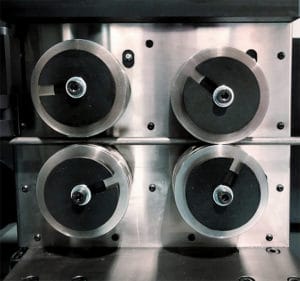

Gear drive wire feed mechanism-no belts to wear

-

Quick change 2 wire size feed rollers that align perfectly

-

All gears are hardened for longevity

-

Wire stabilizer for increased wire form repeatability

-

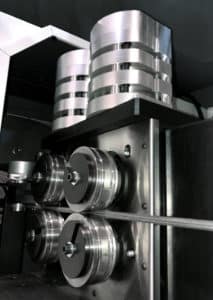

Wide range 2 plane wire straightener

-

Tool drawings for consumables included

-

Super rigid box frame construction

-

Standard 3000 lb powered payoff unit included

Controls/Software Features

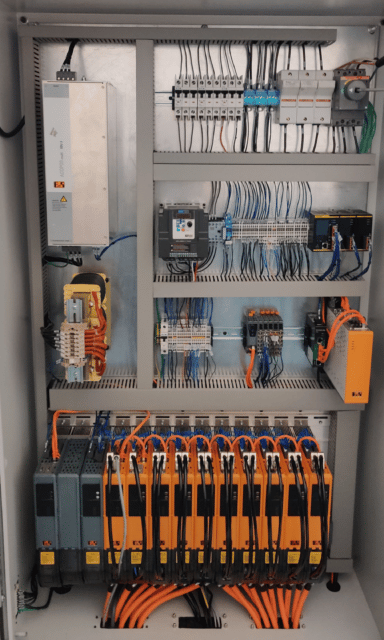

System diagnostics manager for full machine overview

Power usage monitor for machine power usage and efficiency

Active power supplies for boosing DC bus voltage for greater machine performance

Shared DC bus voltage for machine efficiency, extra power is filtered back to the line

Wire position encoder to detect feeder slippage