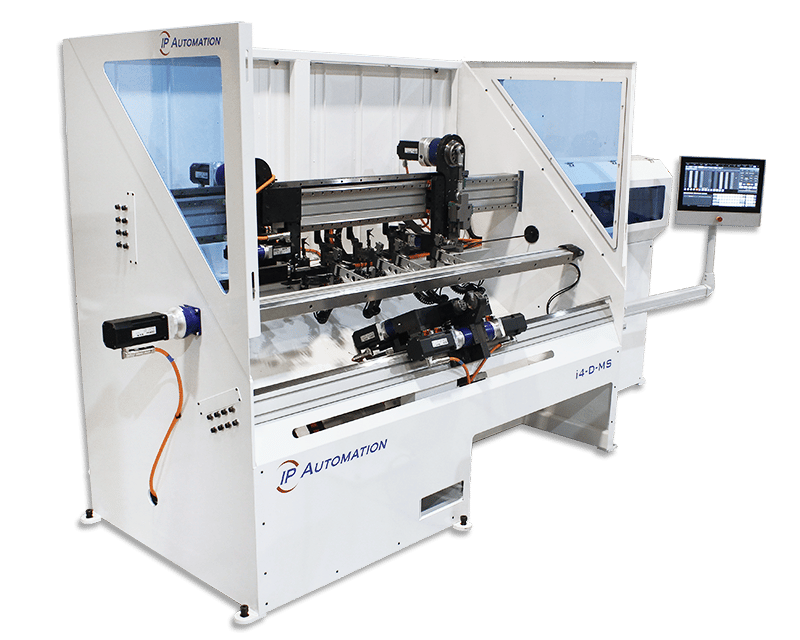

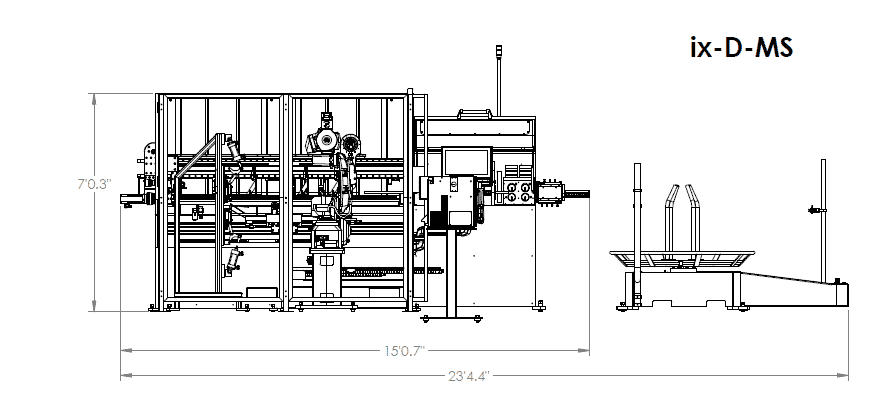

Multi-Stage CNC Wire Benders

i-D-MS Series

Media

Features

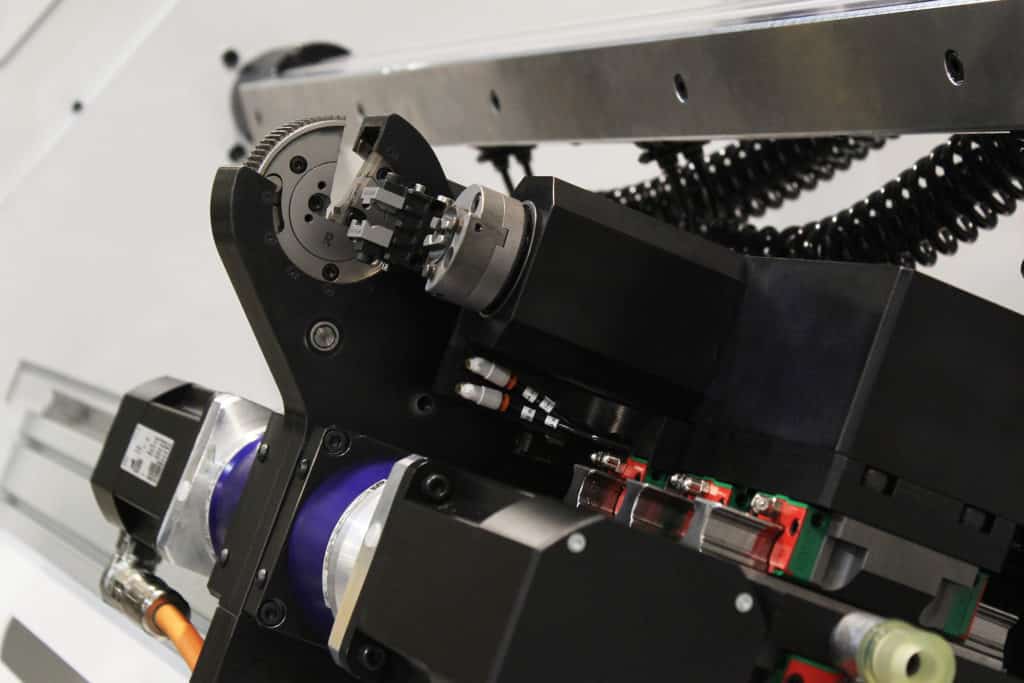

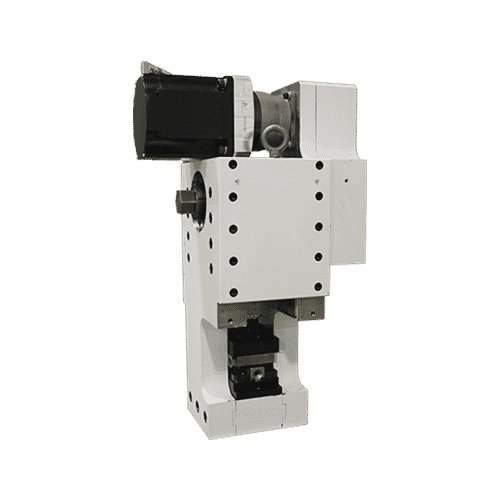

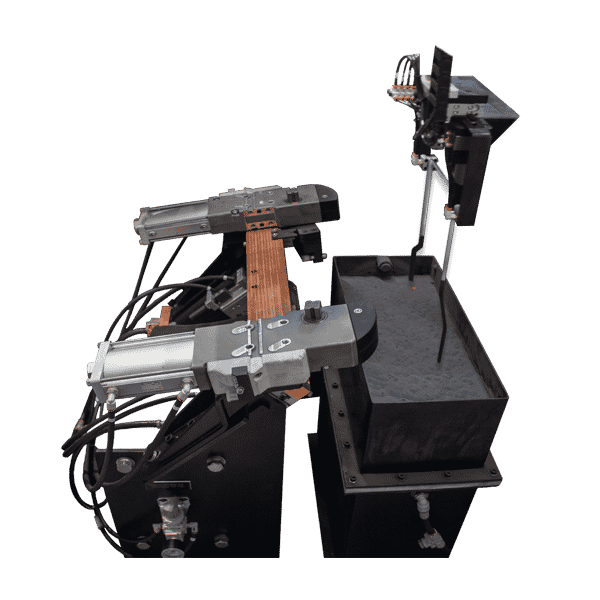

- 20 Servo Axes: X - feed, rotary straightener, C - cutter, Y - bender pin rotation (2X), Z - clamp & rotate, U - tool pivot (2x), P - bend head height (2X), transfer

- Up to 2 radii

- IP Automation engineers and CNC machines all bend heads, cutters and wire feed rollers in-house at reasonable cost with fast turnaround

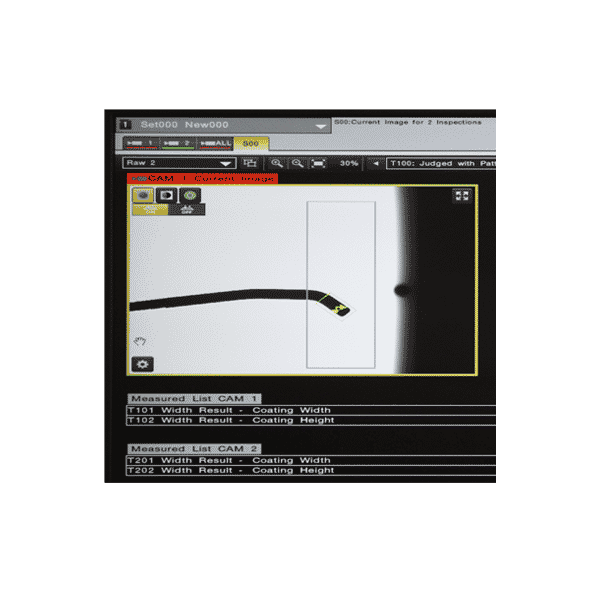

- Intellibend software on Windows 10 operating system

- Length-Rotation-Angle CNC program format

- Integrated production dashboard, batch control functions

- 21.5" multi-touch screen

- Remote connectivity through VPN tunnel

- OPC-UA protocol for industry 4.0

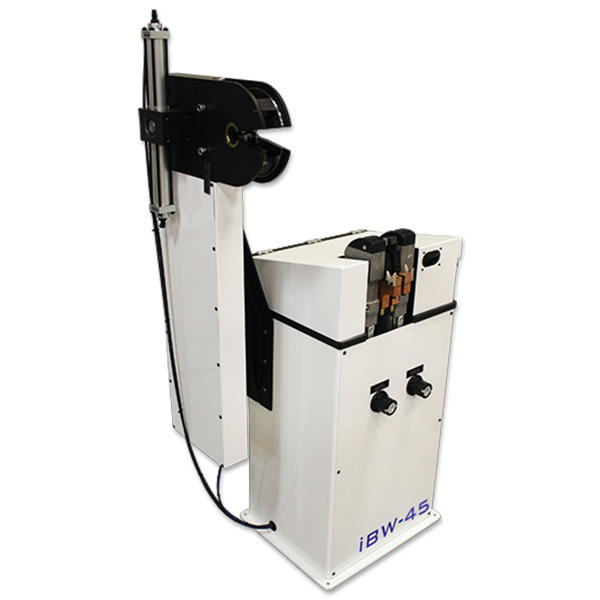

- Available with hopper loaded wire

- Wire payoff with linear motion arm capacity: 3000 lbs. (4500 lbs. option available)

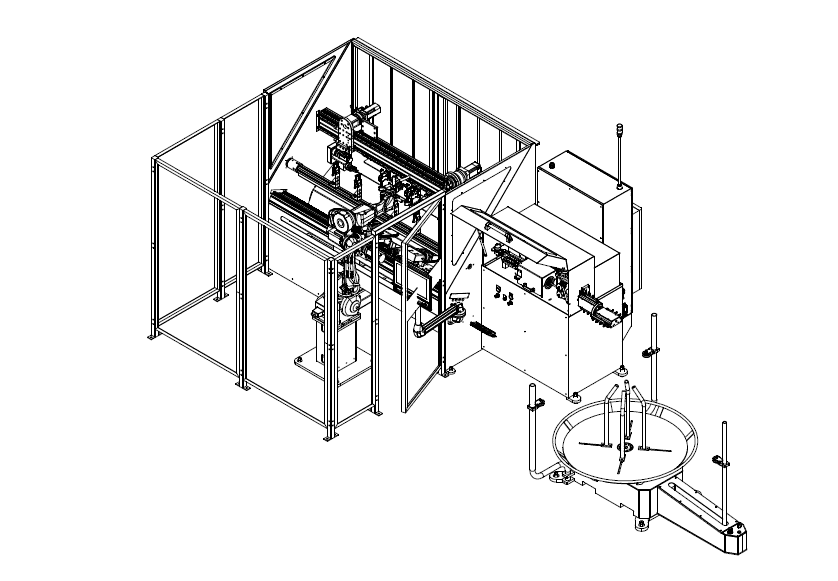

- 7' (2.13m) safety cage with safety interlock door

- Arbor wire straightener

- All feed & bend drive systems have hardened gears and are fully enclosed.

- Quick flip hardened feed rollers for 2 wire sizes

- Linear encoder on wire feed for accuracy and slip detection

- Wire stabilizer

- Regrindable cutter die surface

- Programmable retractable wire guides

- On-site training available

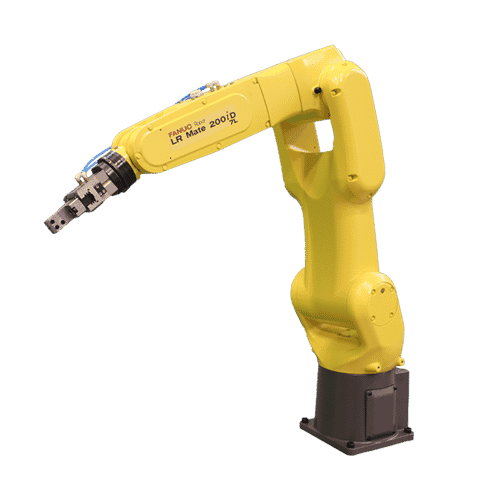

- Robotic integration capable

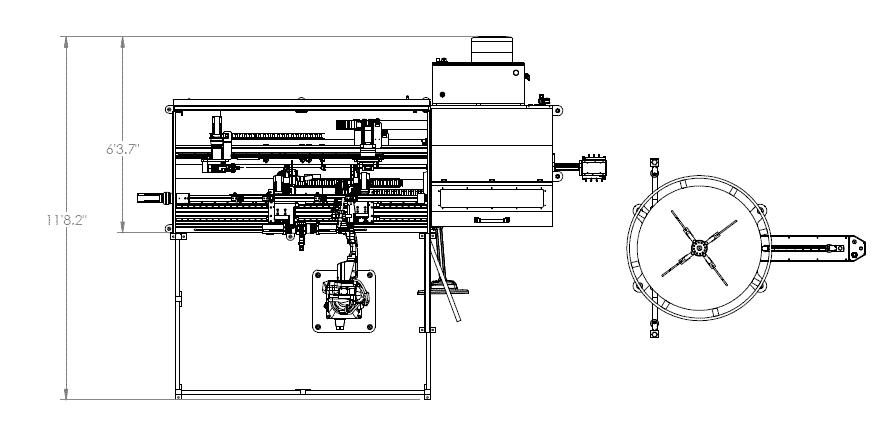

Specifications

*Minimum and maximum diameter capability is influenced by tensile yield of the wire. Contact us for clarification on min/max range for your wire type.