Experts in automating wire forming processes.

Our machines, engineers, and technicians are geared for customized solutions for your company. Achieve your vision of high-speed single piece flow with minimal labor, and zero WIP.

We have expertise in robotic integrations such as: welding, chamfering, assembly, presses, cold Heading, threading, machining, clipping, stress relieving, inspection etc.

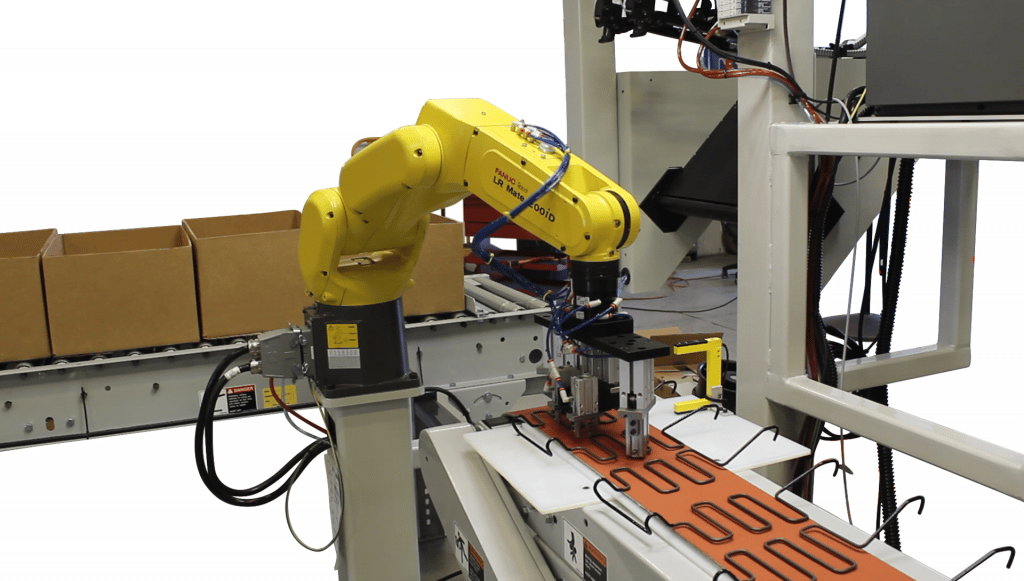

i-D Automation Cell

i-S Automation Cell

i-S Automation Cell

i-S² Automation Cell

i-S² Automation Cell

Flexmat Automation Cells

- Flexible Automation, Run different parts with quick changeover

- Servo adjust-ability for easy setup and minimal tooling

- From coil or magazine feed

- Up to 32 Servo axis

- Up to 6 Bending stations

- Optional Integrated Stress relieving and Nylon or PVC coating Stations

- Built in cooling station

- Vision guided assembly Station

- Secondary station options including assembly by clinching or clipping

- Multiple Wireforms, stamping and plastic inserts can be adapted for assembly

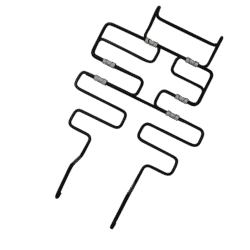

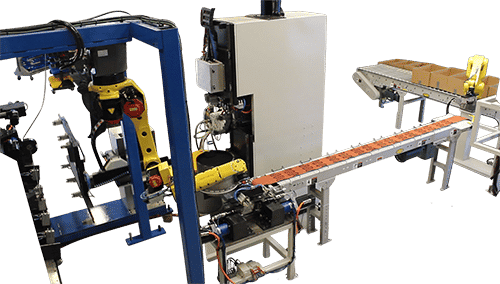

Assembly Cells

- Assembly Cells for automotive components

- Multiple wireforms and assemblied

- Operations include clipping, clinching, spot welding, mig welding and other joining techniques.

- Can be integrated to other machinery for complete autonomous manufacturing

- Cells can be reconfigured for different product lines

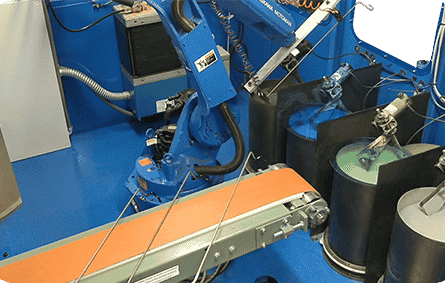

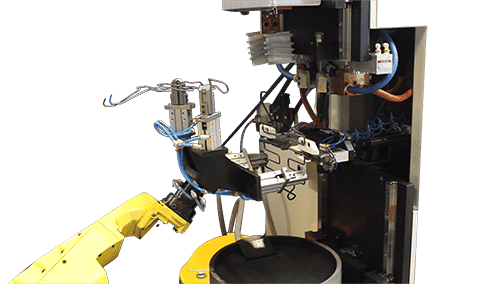

Stress Relieving and Nylon Coating Lines

- Stress Relieving Automation with coating

- Conventional Oven, Resistance, Induction and Infrared Technologies

- Robotic Manipulation for efficient changeover and minimal tooling

- Coating using Nylon,PVC or other thermoplastics

- Multiple Color Coating available at a time

- Standard Powder Hoppers with Auger delivery systems for minimal powder loss

- Standard Cooling racks with optional robotic packaging solutions

- Operator loaded racks or fully automated connected to existing machinery

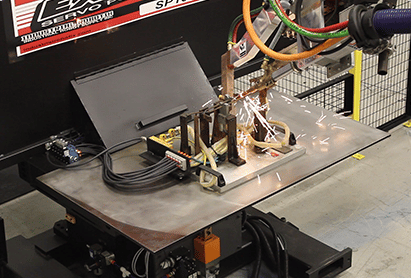

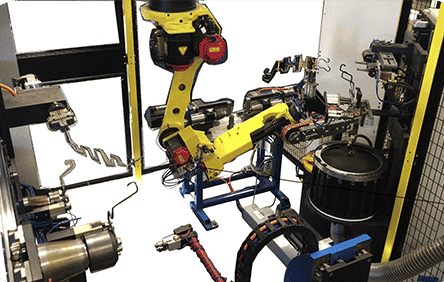

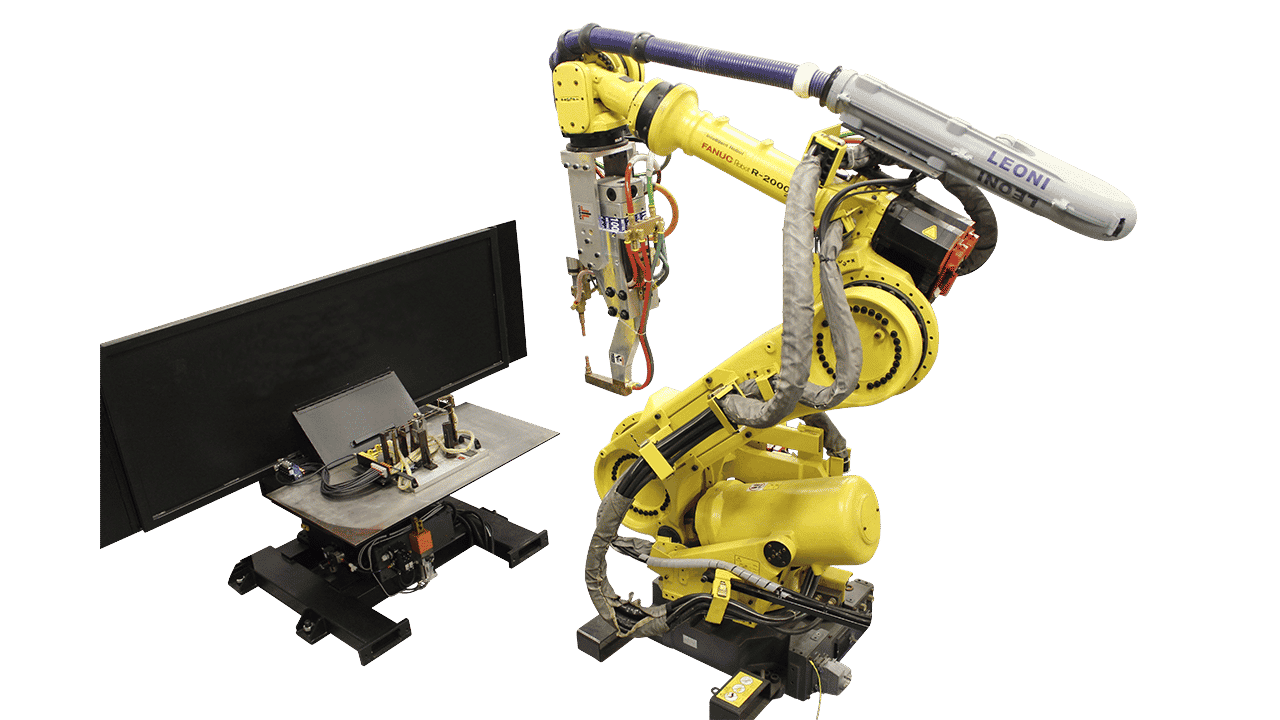

Resistance Welding Cells

- Fanuc R1000iA-80 through R2000iA-210F

- Servo Rotary Table

- Optional Obara or Tolomatic Servo Guns

- Build in quick tooling plates for quick changeover

- RFID capability to minimize setup mistakes

- Light Curtain or Safety scanner operator loaded options

- Can be integrated to multiple wire benders for automatic forming and welding cells

- Optional Automated Tote conveying systems for packaging