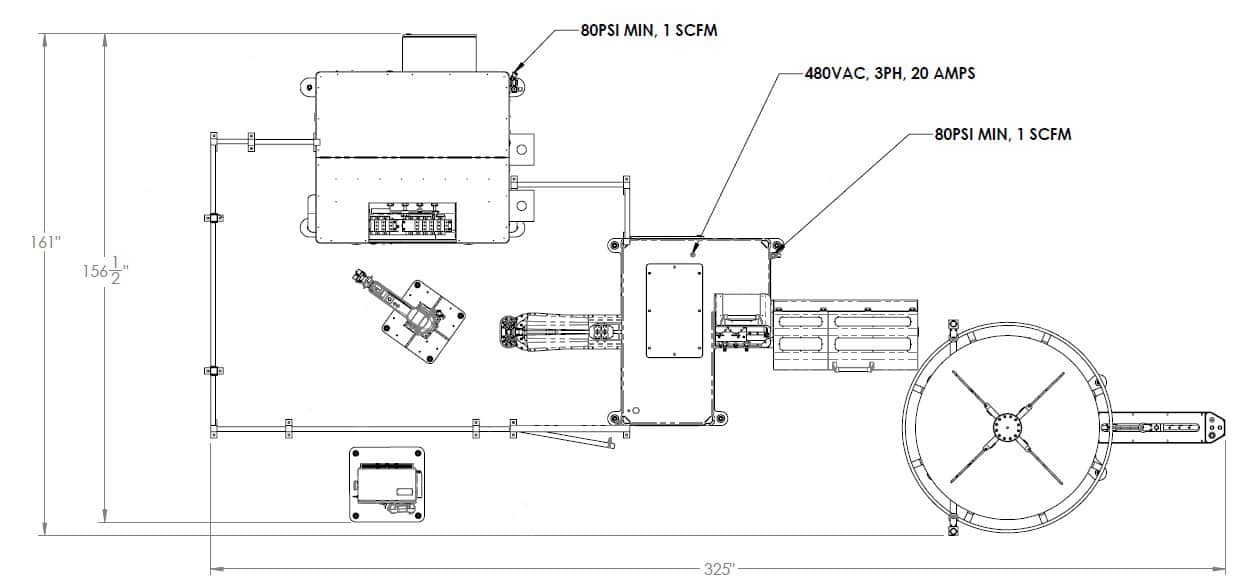

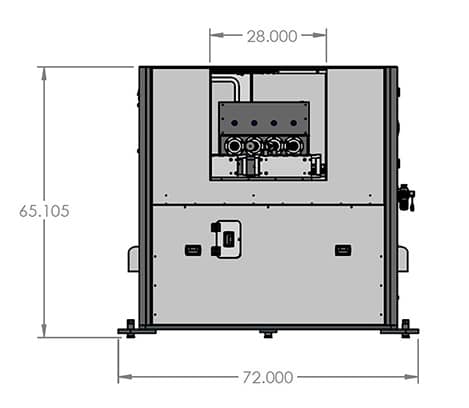

iFM Series Wireform Machining Center

The iFM-10-4, and iFM-13-4 are an innovative breakthrough for wire form secondary operations like chamfering, diameter reducing, threading, milling and cross hole drilling.

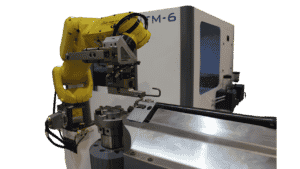

The first of its kind, the iFM is designed for seamless robotic integration with our line of CNC wire bending machines and is fully programmable to adjust to handle a wide range of challenges.

Media

Features

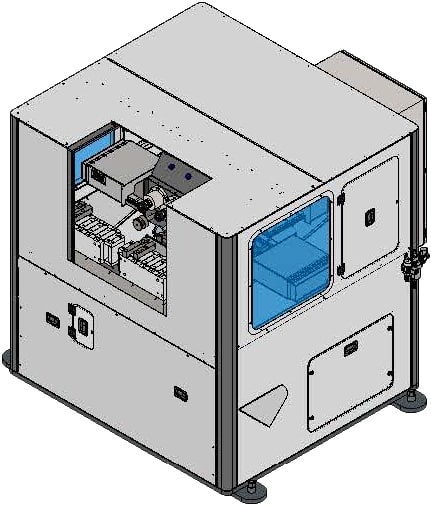

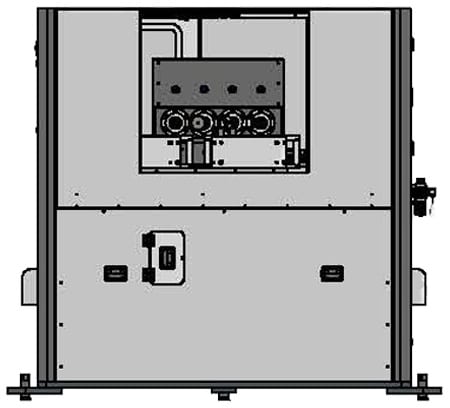

- 2 axis machining center with optional 3rd axis

- 4 spindles for efficient operation

- Chamfer, turn, thread, mill, or drill all in one machine

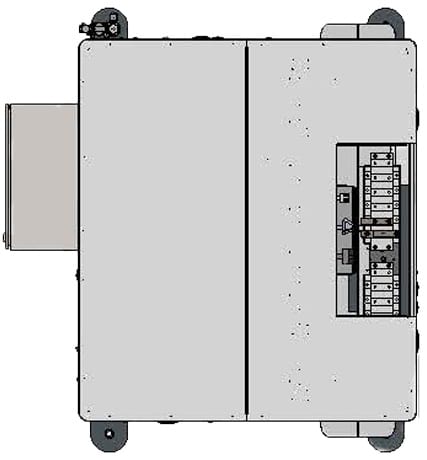

- 10" (25.4cm) touch screen HMI panel with enclosure. Multiple mounting options within reach of umbilical cord

- Automatic sliding access doors

Automatic pneumatic clamping secures or releases parts as they are positioned by the robot. The 4 spindle design allow users to quickly change out tools with standard tool holders. A wizard program on a remote mounted HMI enclosure provides CNC level control with simplified menu options. The 3 Axis option provides the ability to interpolate around the end for milled shapes and special profiles.

The refined simplicity of our intellimate robot end of arm tooling and our programming format make this easy to program and set up with minimal training.

Users can reduce secondary labor costs to near zero, eliminate WIP, and create a completely automated lean cell that was only a dream in the past.

The refined simplicity of our intellimate robot end of arm tooling and our programming format make this easy to program and set up with minimal training.

Users can reduce secondary labor costs to near zero, eliminate WIP, and create a completely automated lean cell that was only a dream in the past.