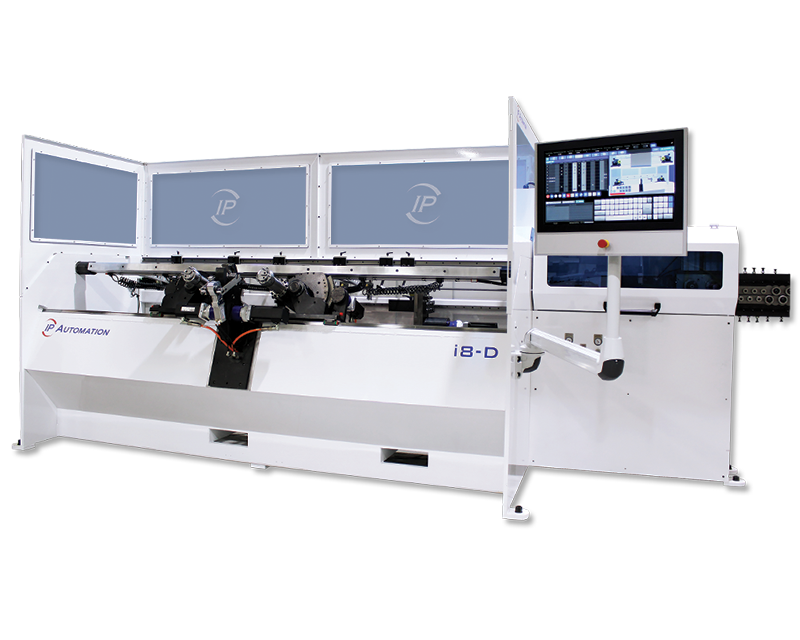

Single Piece Multiple Bend Head 3D CNC Wire Bender

i-S²-T Series

Media

Features

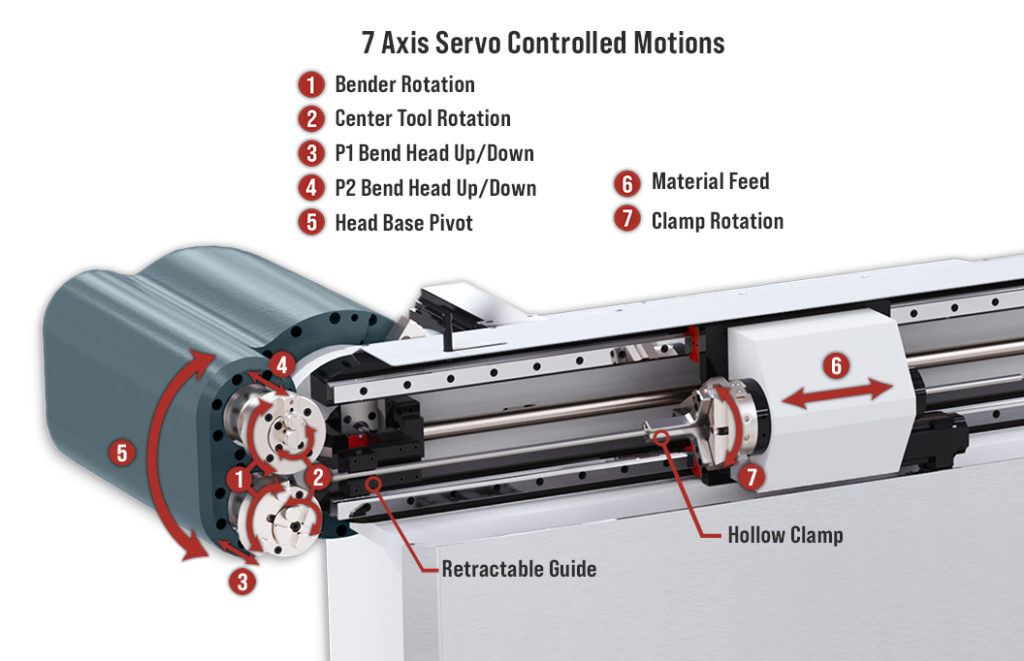

- Two heads with up to 16 radii or custom bending tools

- On-demand re-positioning to either bend head for mandrel, nose, and generated bending

- Servo-controlled bend head height allows for multi-layered tooling

- Out-of-sequence bending is possible with absolute positioning of bend head

- Modular tooling design features easy bending pin replacement

- Off-plane positioning allows for tube bending tools, and fast and accurate mandrel style bending

- Hollow clamp pneumatically grips the material and allows for controlled x-axis motion to the bend head

- Parts can be many meters longer than the machine if properly supported

- Bending head can hold the part stationary, while the clamps travels back to regrip

- Retractable guide provides support during feeding and bending and moves out of the way to allow the moving clamp to move all the way to the bending head

S² (S-squared) bend head

Hollow clamping mechanism and retractable guide

- Intellibend software on Windows 10 operating system

- Length-Rotation-Angle CNC program format

- Production dashboard, with real-time rate & batch programming

- 18.5" multi-touch screen integrated with industrial PC

- Remote connectivity through VPN tunnel

- OPC-UA protocol for industry 4.0

- Custom I/O functions available

- The kiosk control unit houses the computer with Intellibend software and E-stop

- Provides flexible positioning for a variety of cell configurations

- Allows for more clearance if a magazine feed is used

Kiosk control center

- Regrindable cutter die surface

- On-site training available

- Robotic integration capable

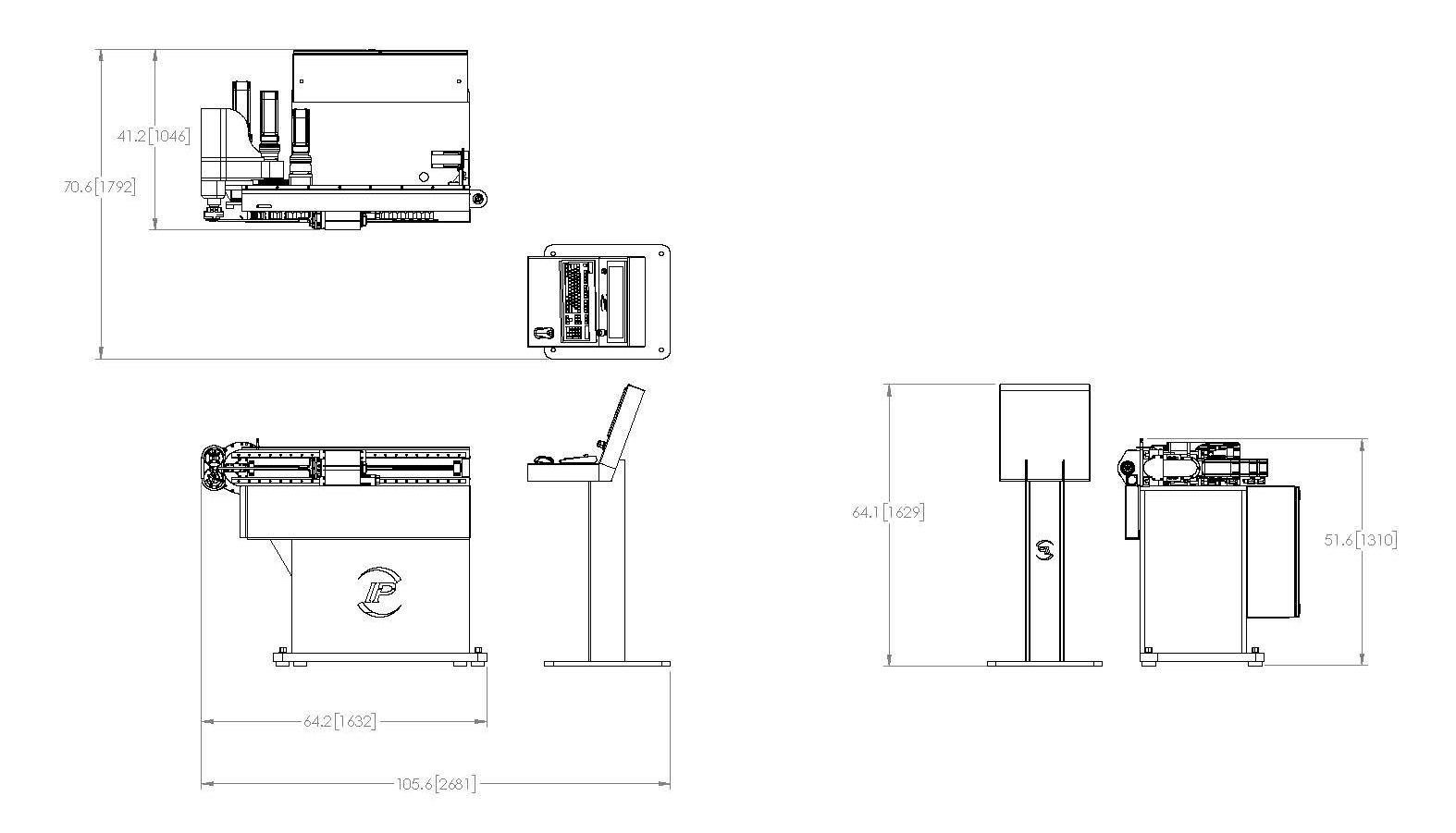

Specifications

*Minimum and maximum diameter capability is influenced by tensile yield of the wire. Contact us for clarification on min/max range for your wire type.