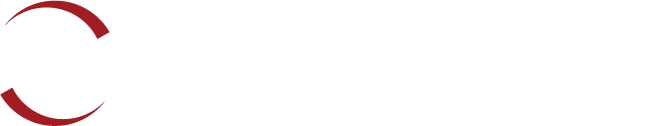

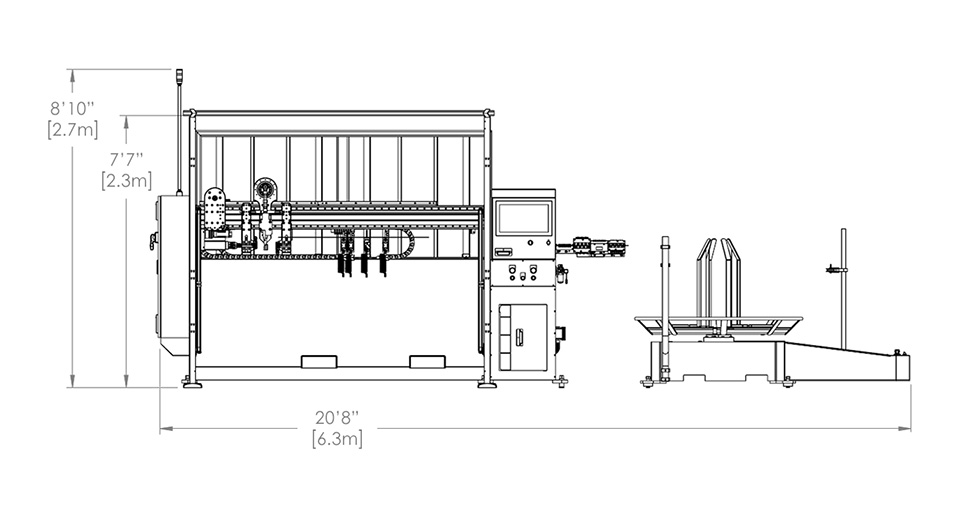

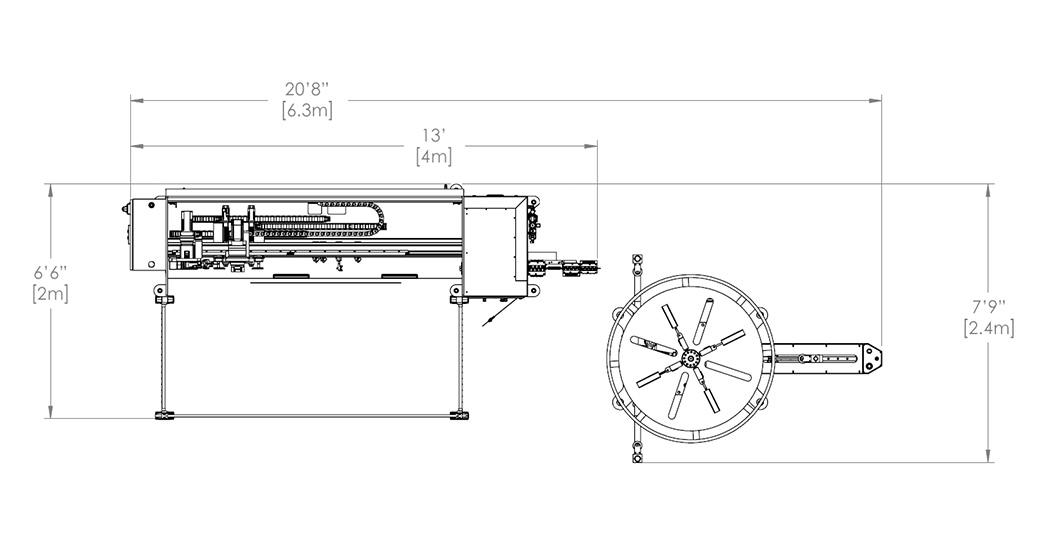

Çift Kafa 3D CNC Tel Bükme Makinası

i-D-SS Serisi

Medya

Özellikler

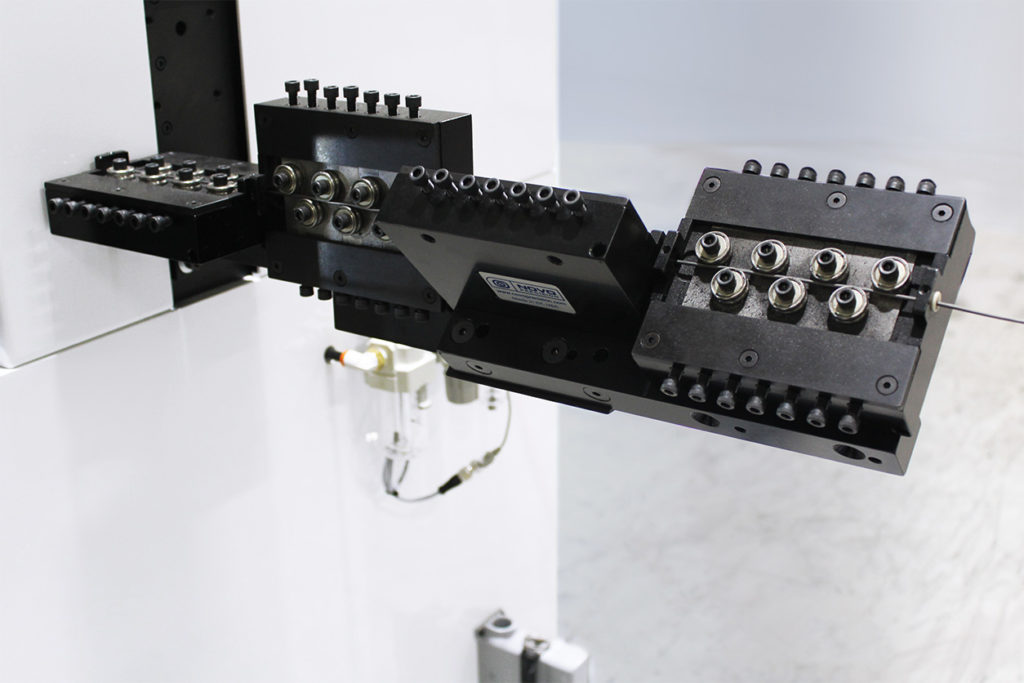

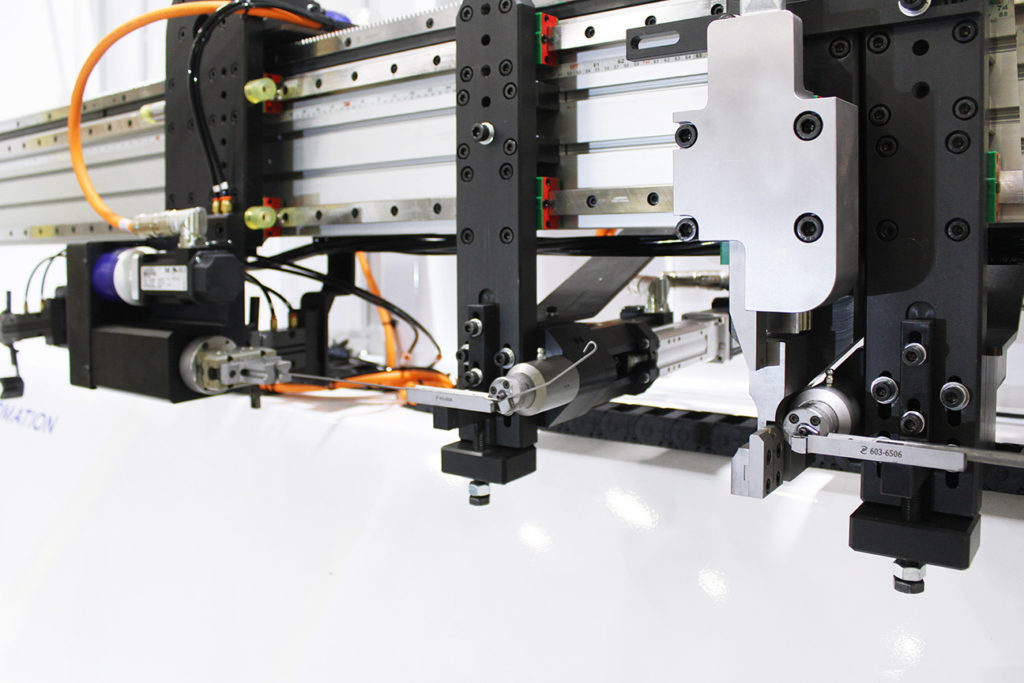

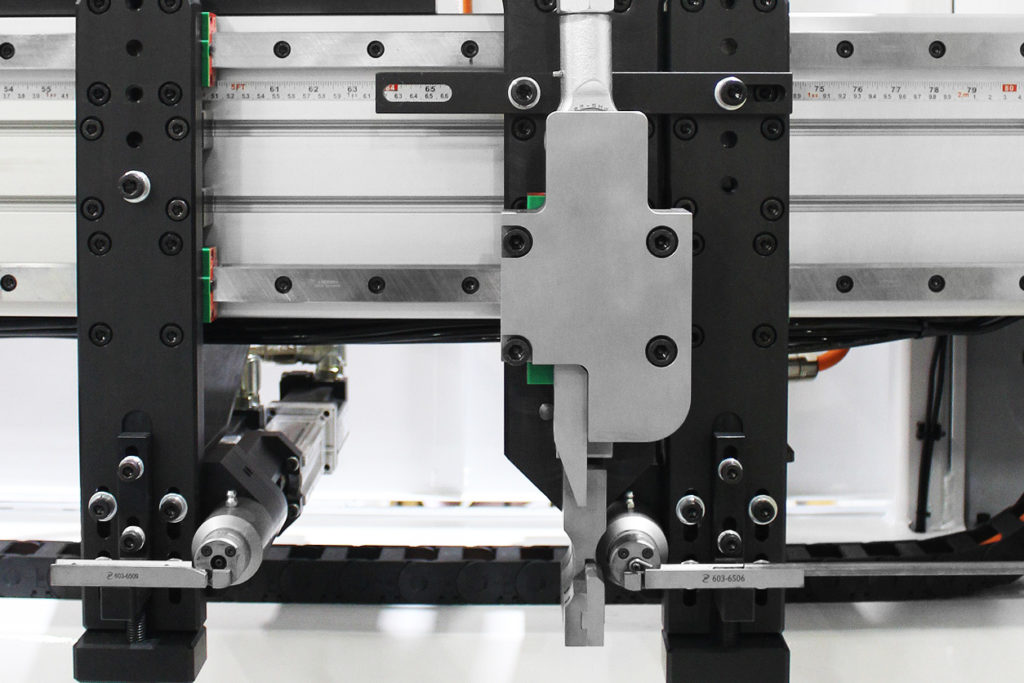

- 8 Servo Ekseni: X - besleme, C - kesici, Y - bükme pimi dönüşü (2X), P - bükme kafası yüksekliği (2X), transfer X Ekseni, transfer dönüşü

- 2 yarıçapa kadar

- IP Otomasyon mühendisleri ve CNC makineleri, tüm bükme kafaları, kesiciler ve tel besleme silindirlerini kendi bünyesinde makul maliyetle ve hızlı geri dönüşle sunar

- Intellibend yazılımı Windows 10 işletim sisteminde

- Uzunluk-Dönme-Açı CNC program formatı

- Entegre üretim kontrol paneli, toplu kontrol fonksiyonları

- 21,5" çoklu dokunmatik ekran

- VPN tüneli üzerinden uzaktan bağlantı

- Endüstri 4.0 için OPC-UA protokolü

- Doğrusal hareket kolu kapasitesiyle tel getirisi: 3000 lbs. (4500 lbs. seçeneği mevcut)

- 7' (2,13 m) güvenlik kafesi, güvenlik kilitleme kapılı

- 4 düzlemli tel düzleştirici

- Tüm besleme ve bükme tahrik sistemleri sertleştirilmiş dişlilere sahiptir ve tamamen kapalıdır.

- 2 tel boyutu için hızlı çevirmeli sertleştirilmiş besleme silindirleri

- Doğruluk ve kayma tespiti için tel beslemede doğrusal kodlayıcı

- Yerinde eğitim mevcut

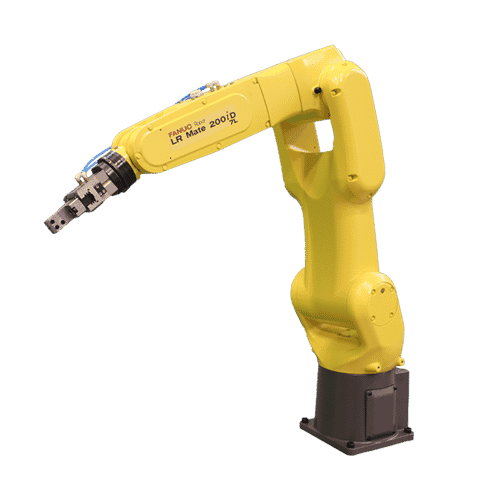

- Robotik entegrasyon yeteneğine sahip

Özellikler

*Minimum ve maksimum çap kapasitesi telin çekme dayanımından etkilenir. Tel türünüz için min/maks aralığının açıklığa kavuşturulması için bizimle iletişime geçin.